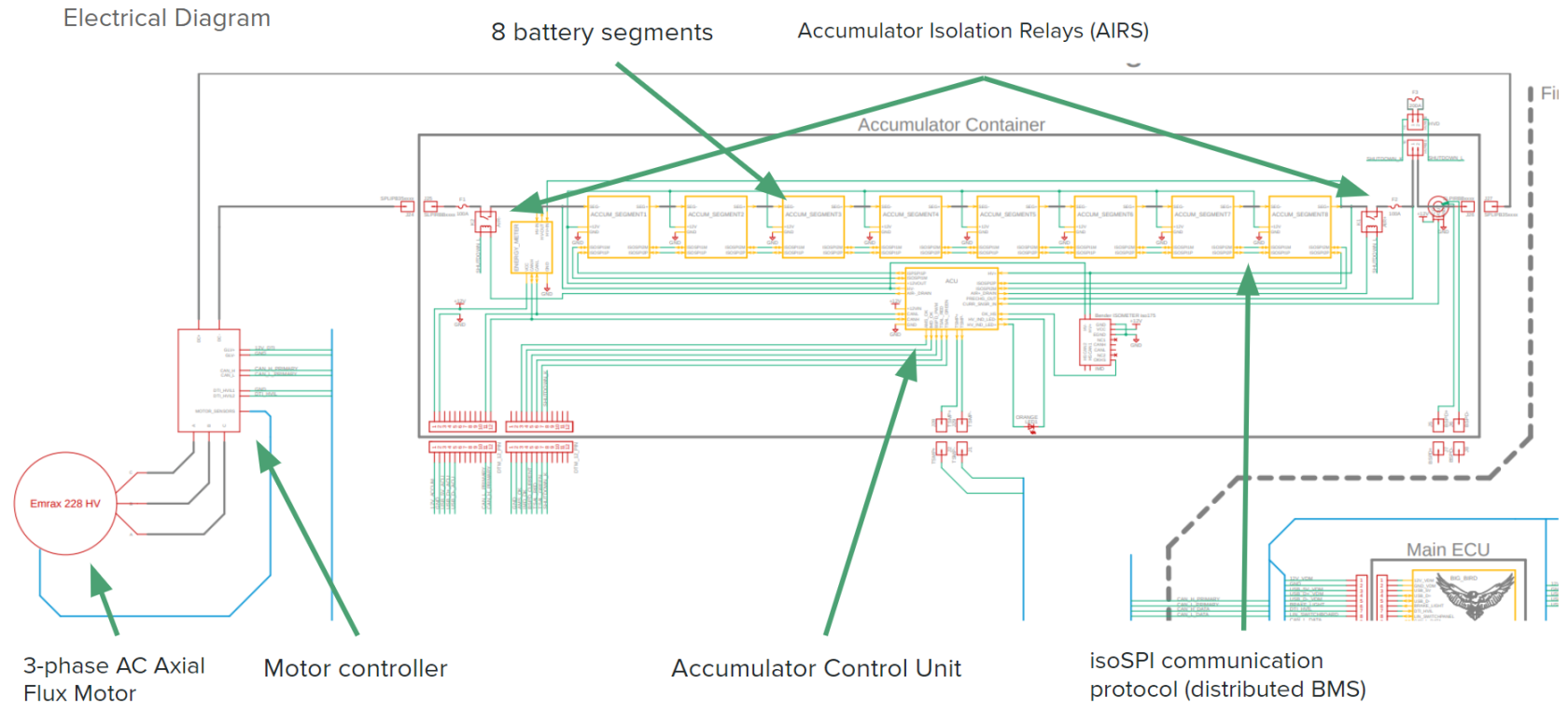

Electrical Architecture

Key Rule Requirements

- Max total battery voltage – 600V (EV3.3)

- Max power output – 80kW (EV3.3)

- Two NO AIRs (accumulator isolation relays) on each accumulator pole

- Precharge & discharge circuit to limit TS inrush current and discharge capacitors (EV5.6)

- TS galvanically isolated from GLV (EV6.5)

- Shutdown circuit drives one AIR (EV7.1)

Design Decisions:

- Cylindrical 2170 cells

- Distributed BMS system

- 128s3p architecture

- Max battery voltage – 537.6V

- Max power output – 72.6kW

- Nominal energy capacity – 6.2 kWh

- Power exceeding 60kW not shown to have distinguishable improved placements in dynamic events (EVW)

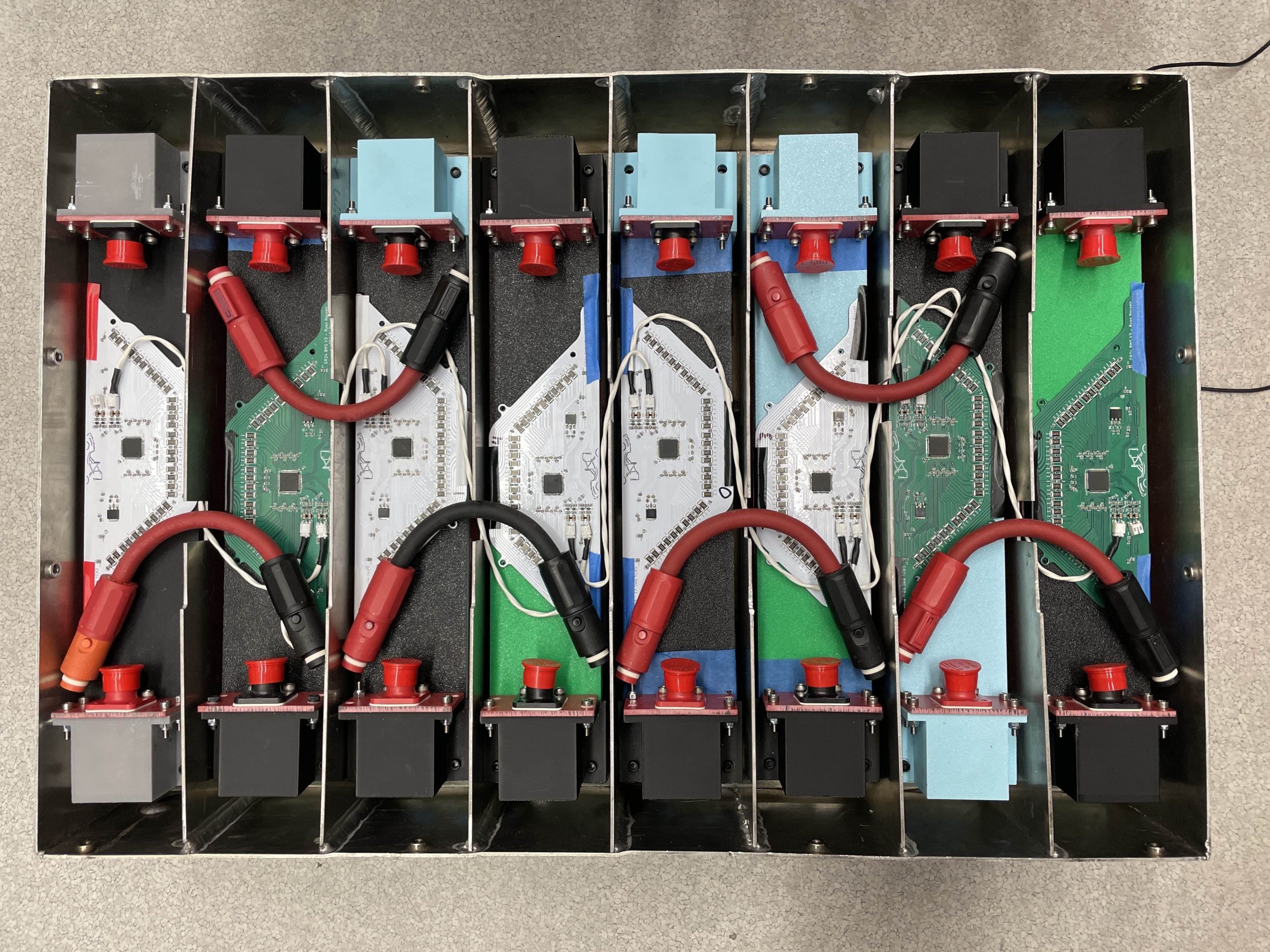

- Split into 8 segments in series

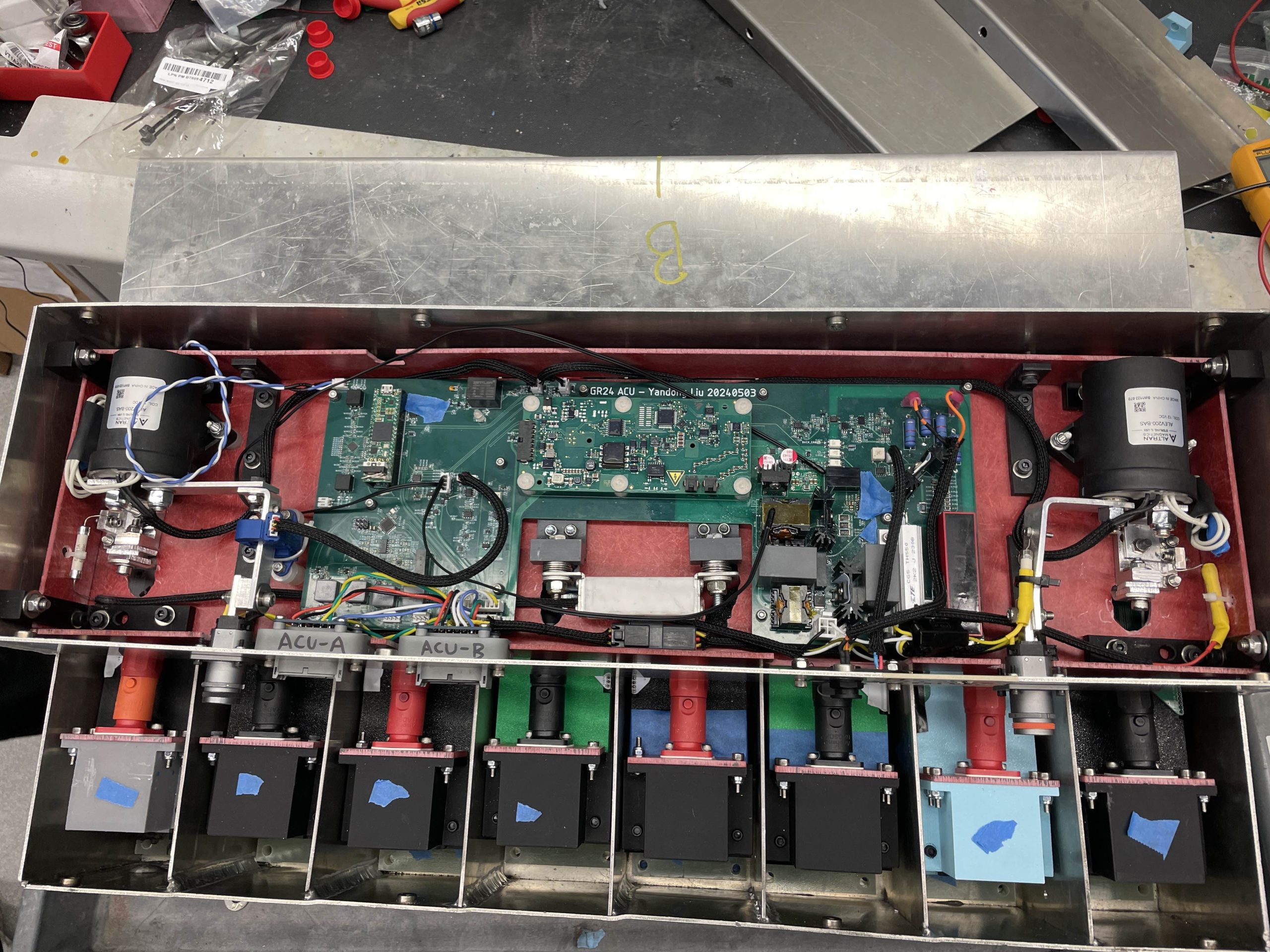

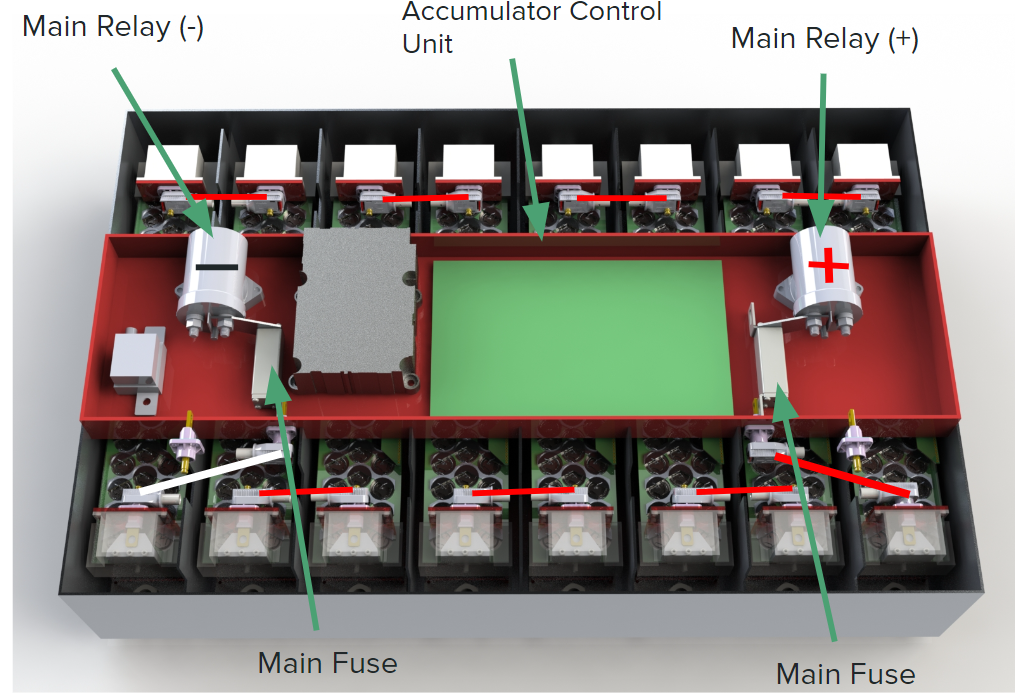

- ACU (Accumulator Control Unit) contains all logic circuitry within accumulator

- Controls relays, fans, lights

- Contains precharge/discharge circuit

- Contains BMS main board

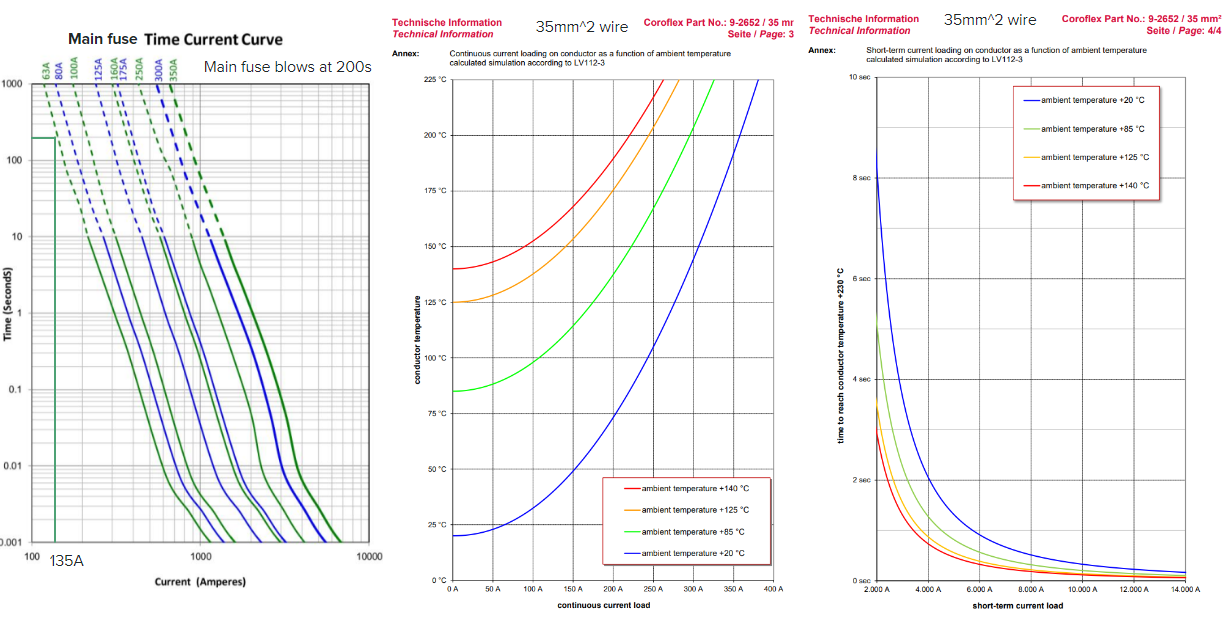

Battery Fusing

Power Loads

- 135A max current (6 seconds during acceleration event)

- 55A Continuous RMS Current (150 seconds during autocross)

Design Decisions:

- 63A main fuse (we want this to blow first)

- 35mm^2 / 2 gauge wire

- Bend radius is 43mm (½ distance between segments) in design, which is 4 times 11mm (wire OD). This is less than the recommended 8 times wire OD so need to keep an eye on cable kink, strain, and wear

- 8mm SURLOK connectors

Fusible Links:

Motivation – Why Wire Bonding?

- No heat interaction with Lithium

- Compared to spot welding

- Integrated fusing (details in following slide)

- Reduced contact resistance

- Quick and safe automated process

- Quality Control (Hesse Mechatronics)

Requirements

- Wire bonds rated for max of 1.75x Max cell discharge current (45A cell, 80A fuse)

- Spec from FSAE Judge

- Specify wire diameter, wire length

- Have Fast and Slow fuse blow out times (160A, 80A)

- 4N Aluminum Wire (99.99 Purity)

- Impurities change resistance

| Blow Time | |

| Current Level 1 (80A) | 30 < t < 300 sec |

| Current Level 2 | 5 sec < t < 15 sec |

| Current Level 3 | 0.2 sec < t < 1 sec |

| Current Level 4 (160A) | 0.05 sec < t < 0.15 sec |

MATLAB Simulation of 1mm Round Wire

Lumped Capacitance Model w/ Temperature Dependence:

Fuse Blowout Times for 42mm wire at various diameters

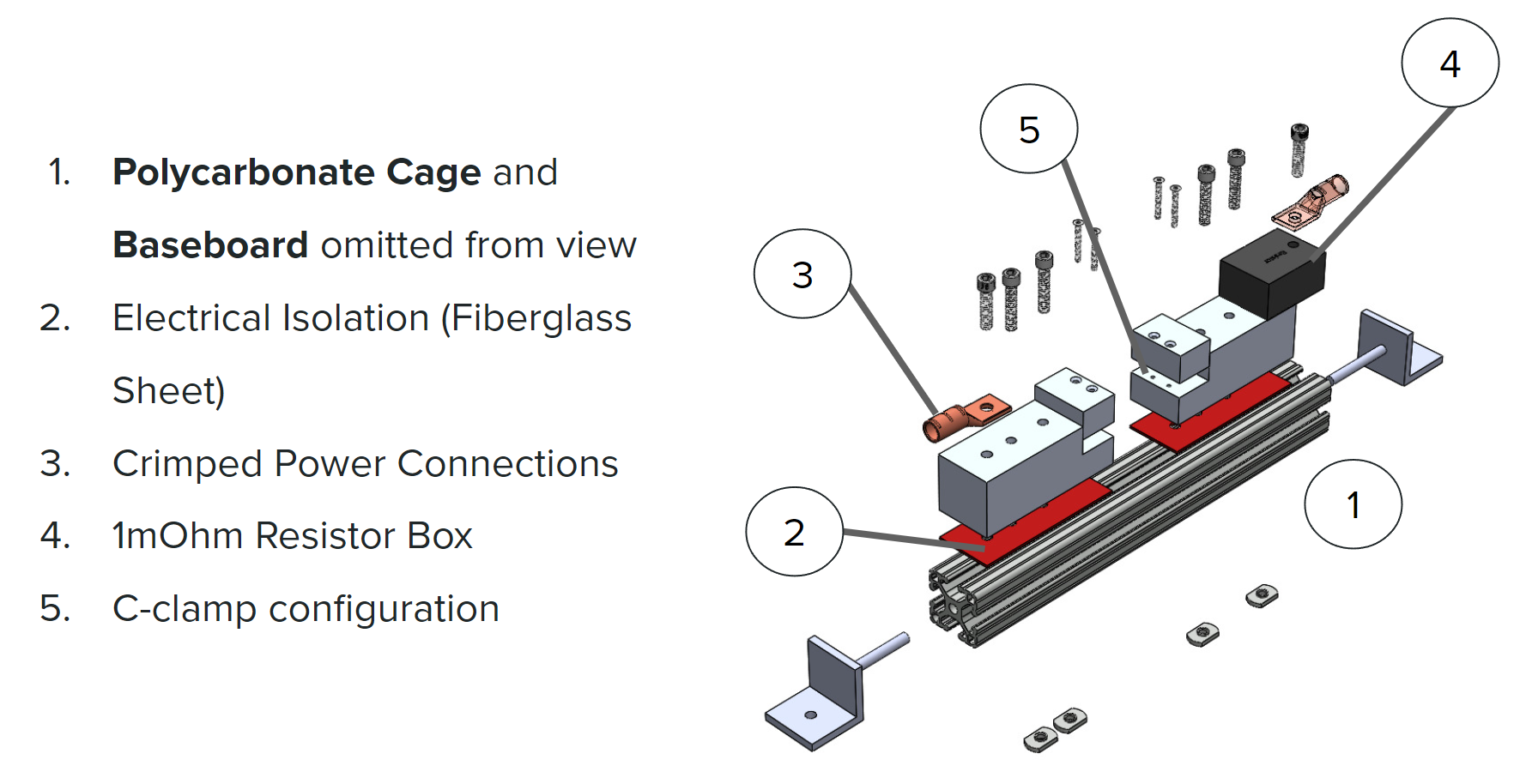

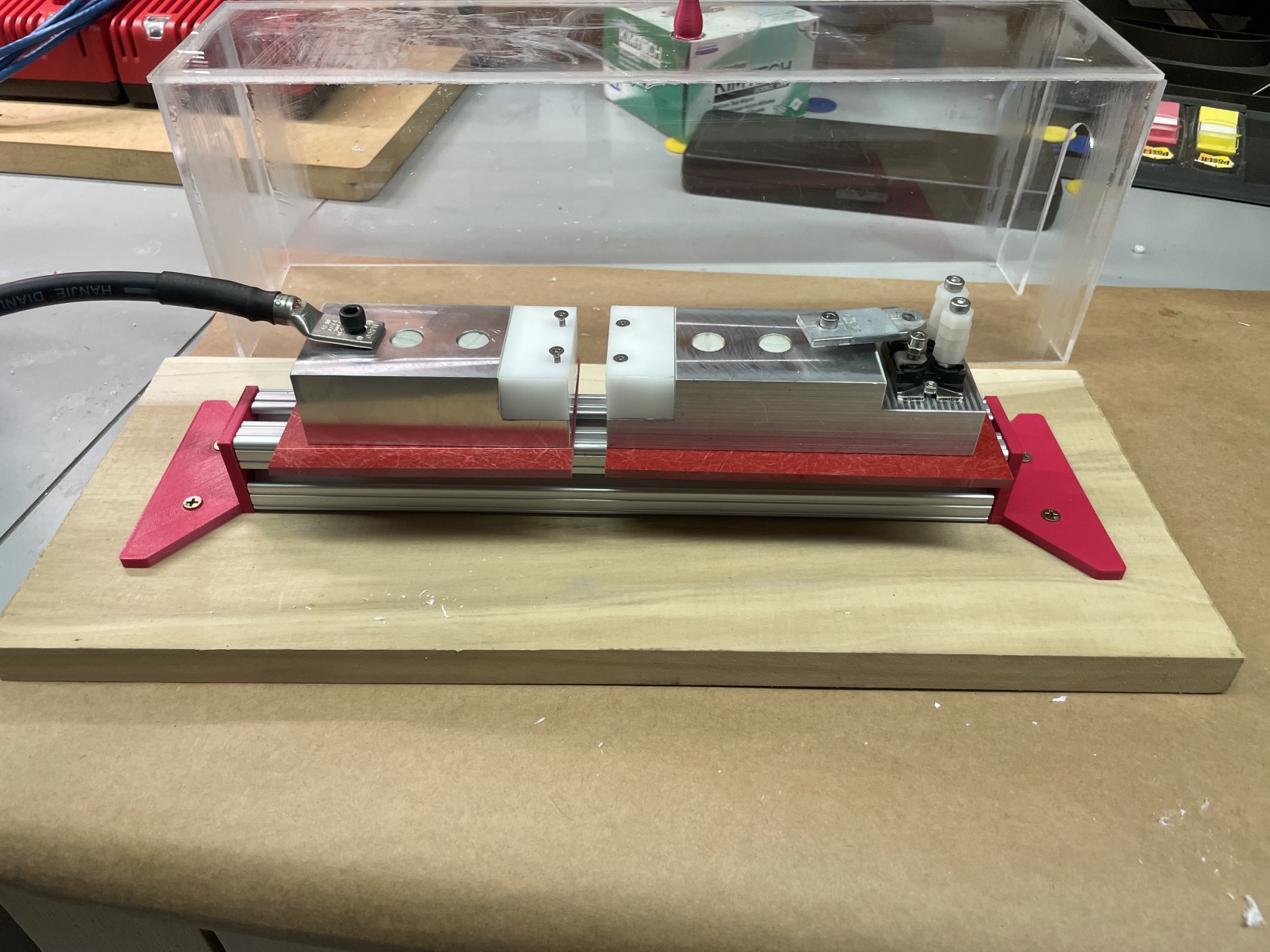

Test setup:

Battery Thermals

Simulated Power Loads for endurance event pack level adiabatic sim:

- 35kW RMS power

- 76A RMS current

- 135A peak current

Current throttled to 70%:

Battery temps increase 5°C per lap /20 laps

Transient Cell Temperature Simulation:

Assumptions

- 25°C Initial Temperature

- 40°C Coolant Temperature

- 20kW continuous pack power (2.3W each cell)

Hotspot temps w/ 60 min end condition:

Cold Plate Initial Design & Testing:

Key Design Points:

- No leak paths within of cell enclosure

- Prioritizing for now on low pressure drop

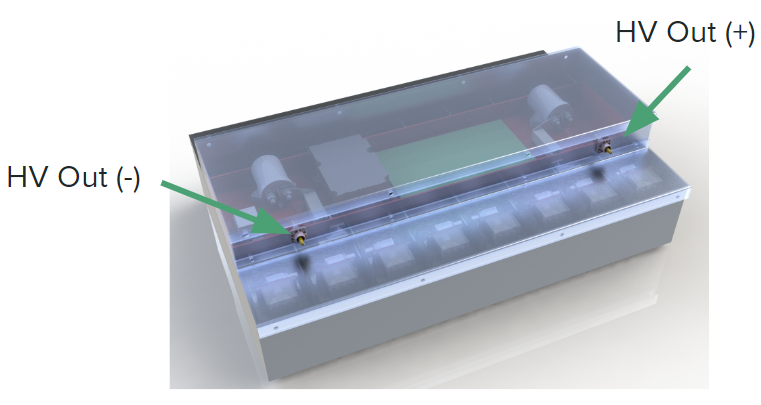

Accumulator Container

Key Rule Requirements

- Made from steel, aluminum, or composite (F10.2)

- Can be welded, fastened, or bonded (F10.2)

- Each segment separated with walls and lid (F10.3)

- 10mm holes for air flow or minimum size for cable routing (F10.4)

- Amount and size of mounts to chassis specified by accumulator weight or mount location (corner attachment) (F10.5)

- Maintenance plugs accessible immediately after opening accumulator lid and not necessary to move or remove any other components (EV5.3)

- New rule*

Design Decisions:

- Accumulator sized to fit & mount into chassis

- Experiment with welded aluminum by Neal Feay, alternative is fastened steel

- Prioritizing low tolerance for segment fitment

- Segments fastened instead of friction fit

- Second layer dimensioned to not be above maintenance plugs

Overview of Design Decisions:

- Segments fastened instead of friction fit

- Two box, three lid design allows easy access to maintenance plugs

- Adjustable mounting to account for inaccuracies in chassis fabrication

- Emphasis on ease of fabrication

- 6061 Aluminum (as per rule F.10.2)

- Box utilizes a welded (F.10.2) construction

- Welding to be done by professionals

- Prioritizing greater tolerance for segment fitment

- Lid utilizes a bent sheet metal construction

– Sized to fit and mount to the chassis

Lid Attachment:

- ¼”-20 hex head bolts + captive nuts

- Positively locked with reusable threadlocker

- Segment box lids are designed for simplest manufacturing

- Best method for accurate bends will be determined during testing phase

- Lightweight Fiber Gasket strips to prevent water infiltration

Electronics Tray

Separate compartment within accumulator that houses control electronics.

Changed to mid-pack fuse design instead of two fuses at each end: