Key Rule Requirements

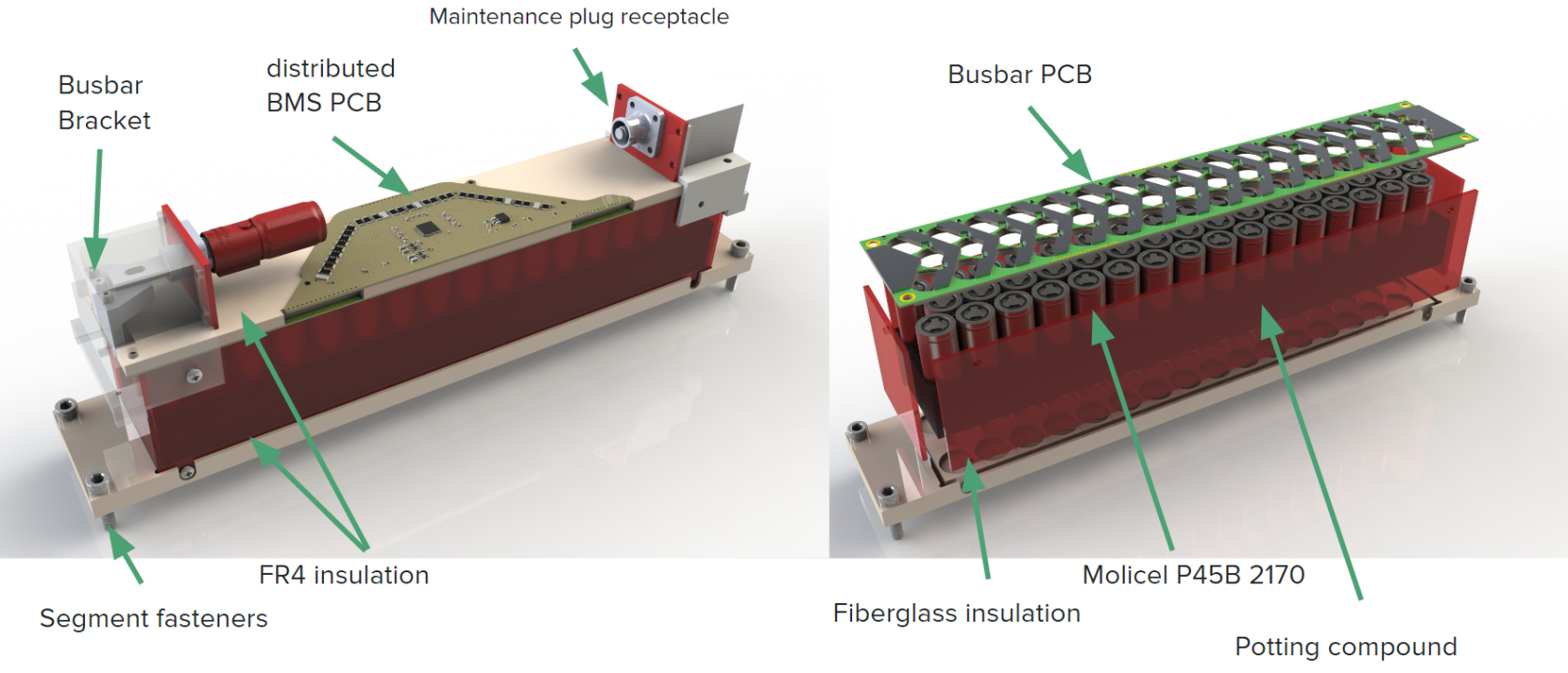

- Max segment voltage – 120V (EV5.1)

- Max segment energy – 6MJ (EV5.1)

- Electrically insulated with non flammable material on top and on the side of each segment (EV5.2)

- Segments connected using positively locking, tool-less maintenance plugs (EV5.3)

- Each parallel cell needs to be fused (EV6.6)

Design Decisions:

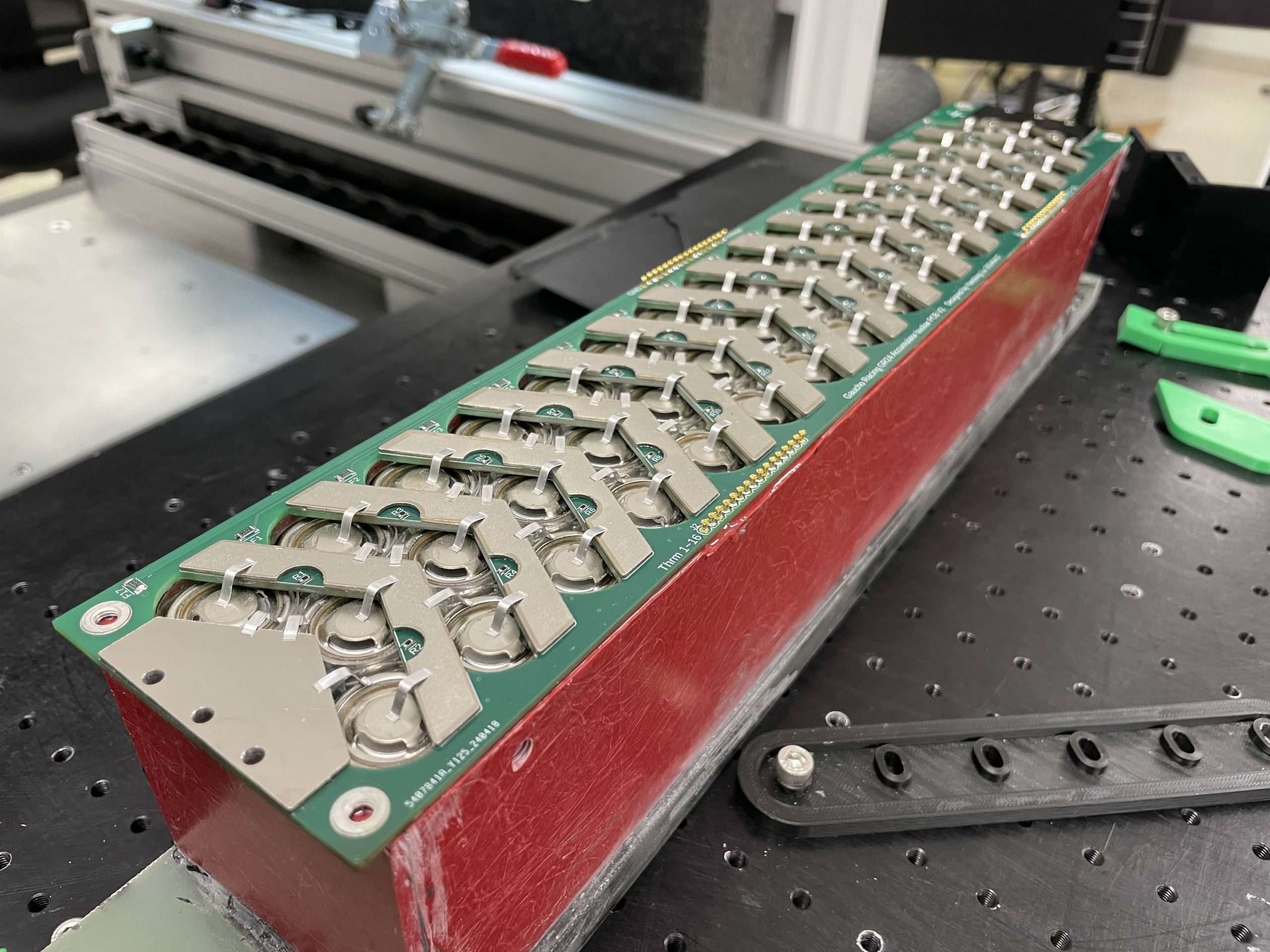

- 16s3p segment architecture

- Each ADI BMS IC can handle 8 voltage channels

- Wire bonded fusible links for each parallel cell

- Fully CNC’d cell connections

- No cooling necessary

- Fiberglass panel insulation on the sides, kapton film insulation on top and bottom

- Cells potted with electrically insulating, thermally conductive epoxy

Fusible Links

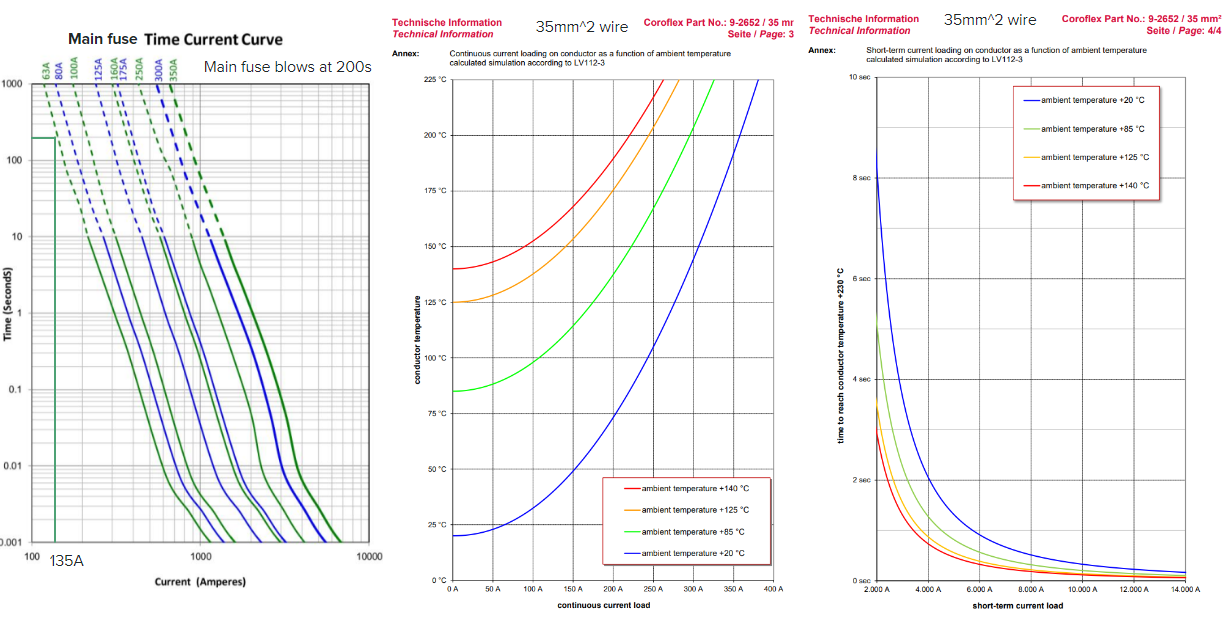

Power Loads

- 135A max current (6 seconds during acceleration event)

- 55A Continuous RMS Current (150 seconds during autocross)

Design Decisions:

- 63A main fuse (we want this to blow first)

- 35mm^2 / 2 gauge wire

- Bend radius is 43mm (½ distance between segments) in design, which is 4 times 11mm (wire OD). This is less than the recommended 8 times wire OD so need to keep an eye on cable kink, strain, and wear

- 8mm SURLOK connectors

Fusible Links:

Motivation – Why Wire Bonding?

- No heat interaction with Lithium

- Compared to spot welding

- Integrated fusing (details in following slide)

- Reduced contact resistance

- Quick and safe automated process

- Quality Control (Hesse Mechatronics)

Requirements

- Wire bonds rated for max of 1.75x Max cell discharge current (45A cell, 80A fuse)

- Spec from FSAE Judge

- Specify wire diameter, wire length

- Have Fast and Slow fuse blow out times (160A, 80A)

- 4N Aluminum Wire (99.99 Purity)

- Impurities change resistance

| Blow Time | |

| Current Level 1 (80A) | 30 < t < 300 sec |

| Current Level 2 | 5 sec < t < 15 sec |

| Current Level 3 | 0.2 sec < t < 1 sec |

| Current Level 4 (160A) | 0.05 sec < t < 0.15 sec |

MATLAB Simulation of 1mm Round Wire

Lumped Capacitance Model w/ Temperature Dependence:

Fuse Blowout Times for 42mm wire at various diameters

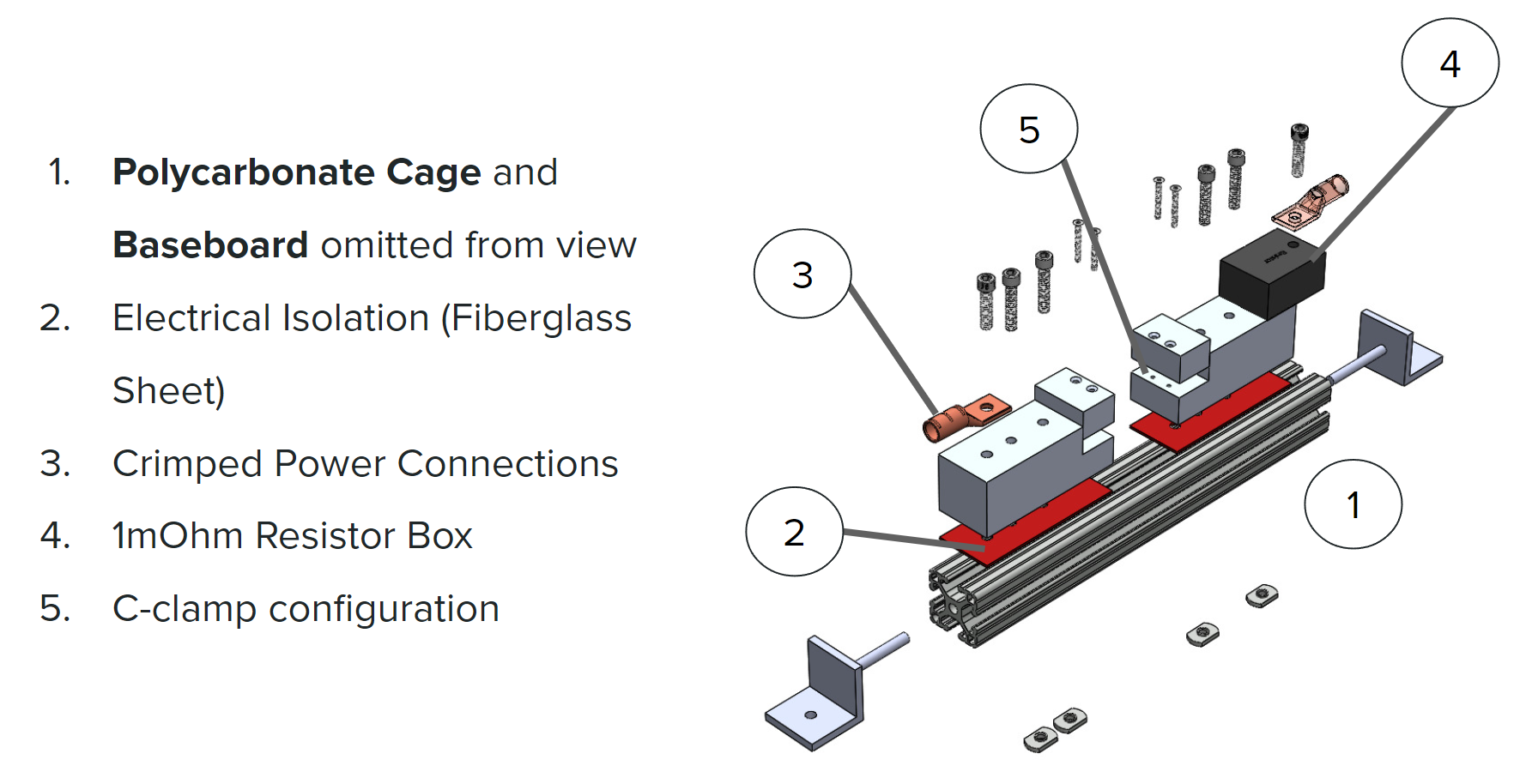

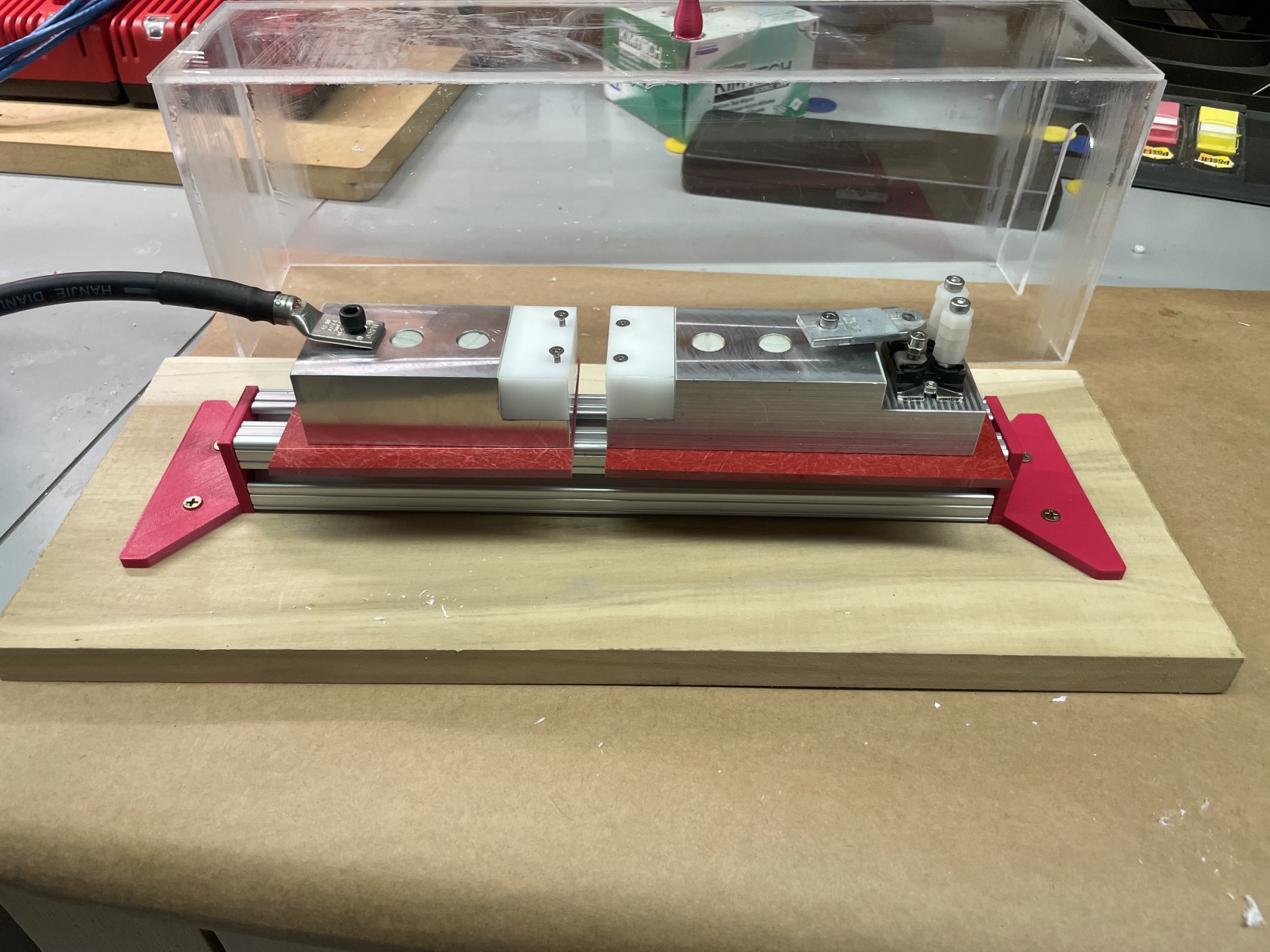

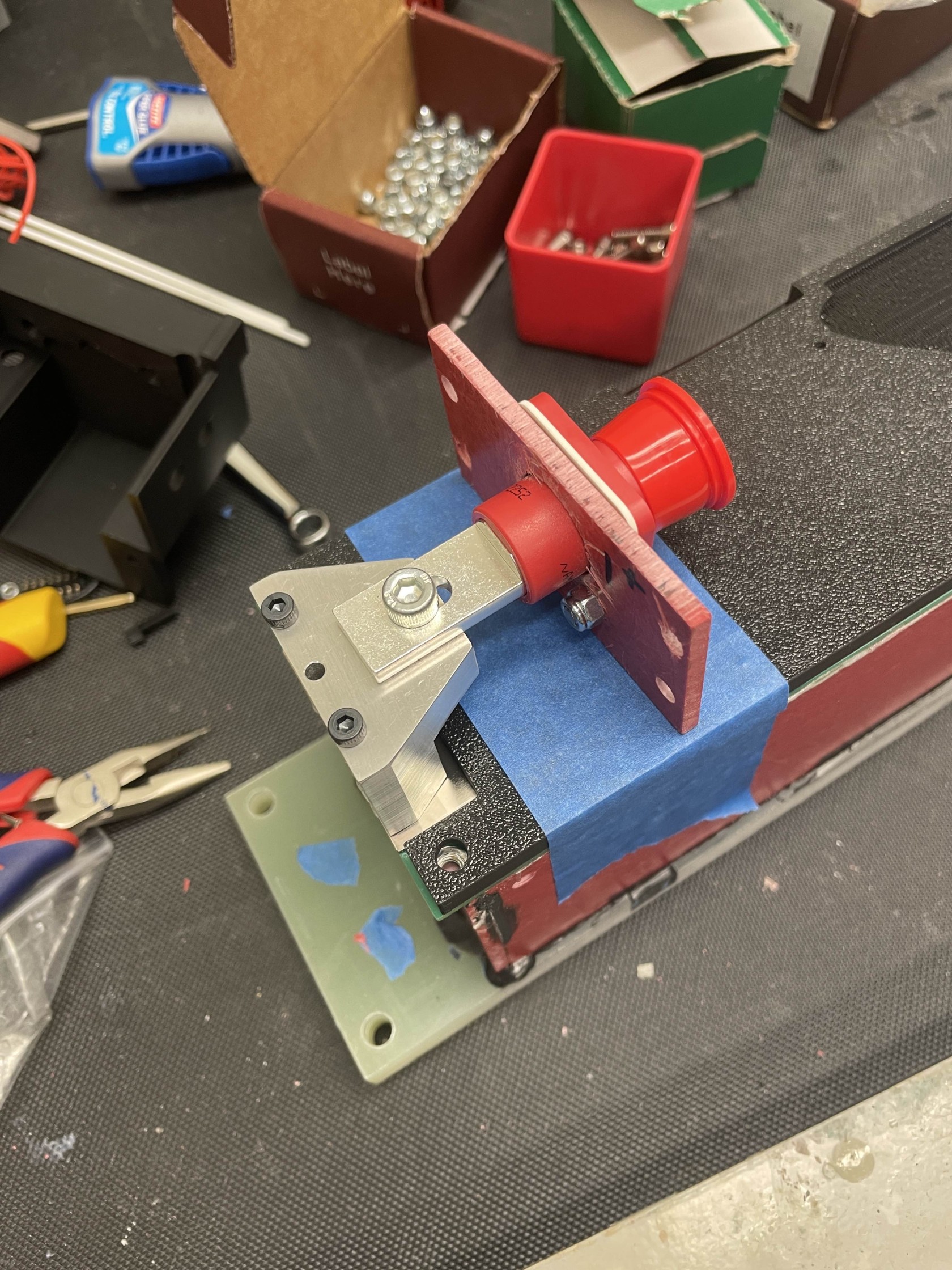

Test setup: