Introduction

Spin coaters can spread thin and flat substrates onto wafers very evenly using centrifugal force. A vacuum chuck holds wafers using suction as the spin coater spins.

Purpose

To design a wafer holder for the CNSI clean room that can center wafers (3″ & 4″) onto the vacuum chuck. The wafers need to spin without wobbling. The holder also needs to be resistant to acetone splashes, as acetone is often used to clean wafers.

Process

A holder was designed in Solidworks and multiple copies of slightly varying dimensions were 3D printed to perfectly center both 3″ and 4″ wafers. ABS plastic experiences thermal shrinkage of about 2%.

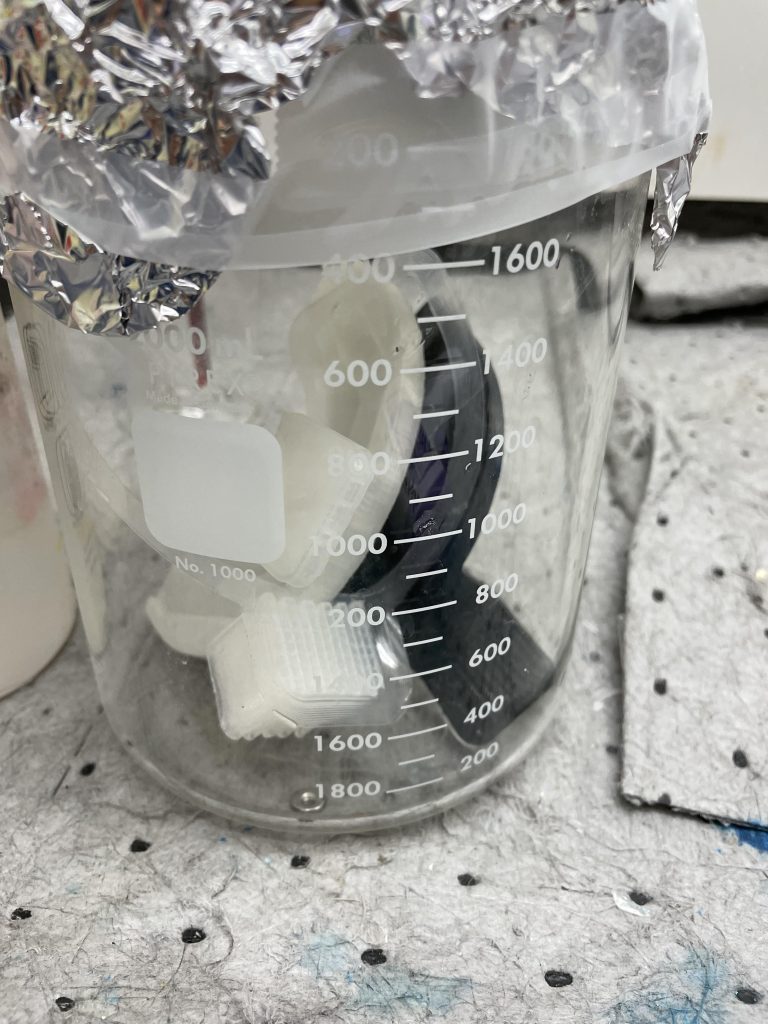

After the dimensions were dialed in, a nylon version was 3D printed to test acetone resistance. An ABS version was set inside a beaker with an acetone version, and acetone was squirted into the beaker. The beaker was covered and left to sit for three hours.

The ABS holder was deformed while there was no visible damage to the nylon version.

Conclusion

The nylon wafer holder is now being used by the CNSI cleanroom to mount and center 3″ and 4″ wafers onto their spin coater.