-

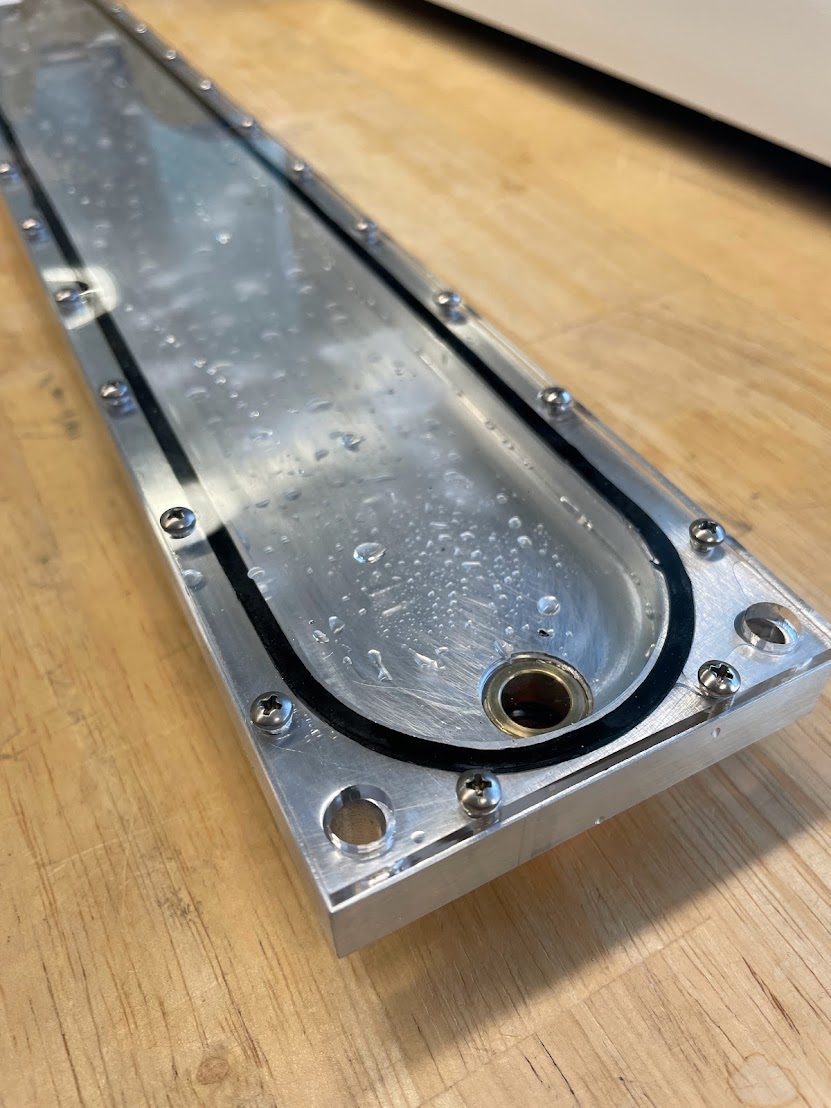

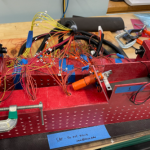

FSAE GR24 Battery Cooling Cold Plate Leak Test

Jason

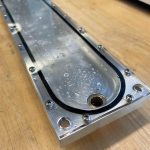

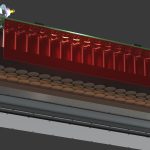

Purpose Battery water cooling was chosen instead of air cooling for two main reasons: The risks and cons of water cooling are: Method A basic cold plate was designed and machined to cool the bottom ends of the cells, consisting of a single large channel with no internal fin geometries. The gasket is laser cut…

-

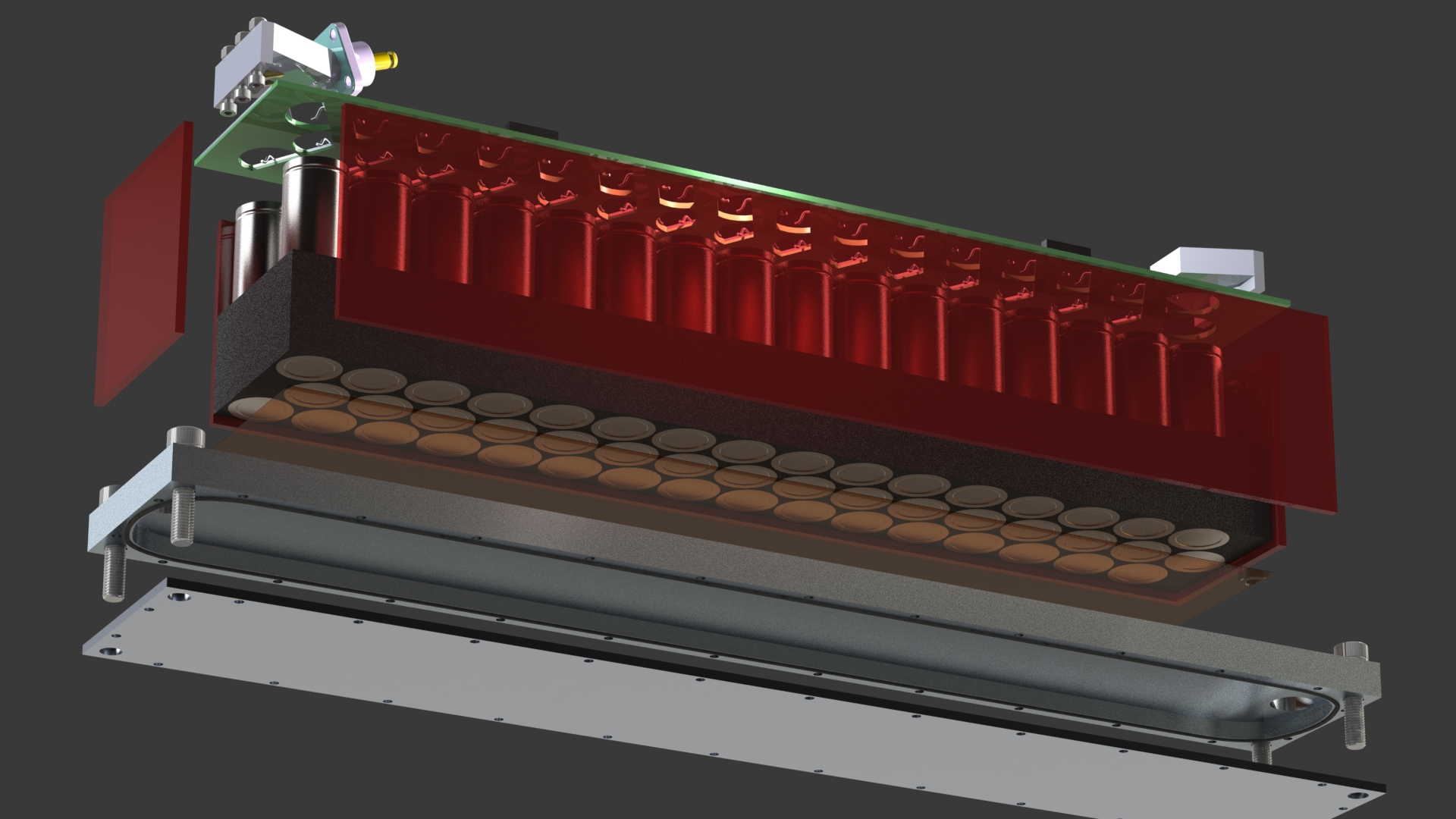

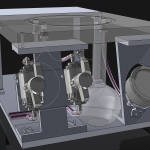

FSAE GR24 Battery Segment Design

Jason

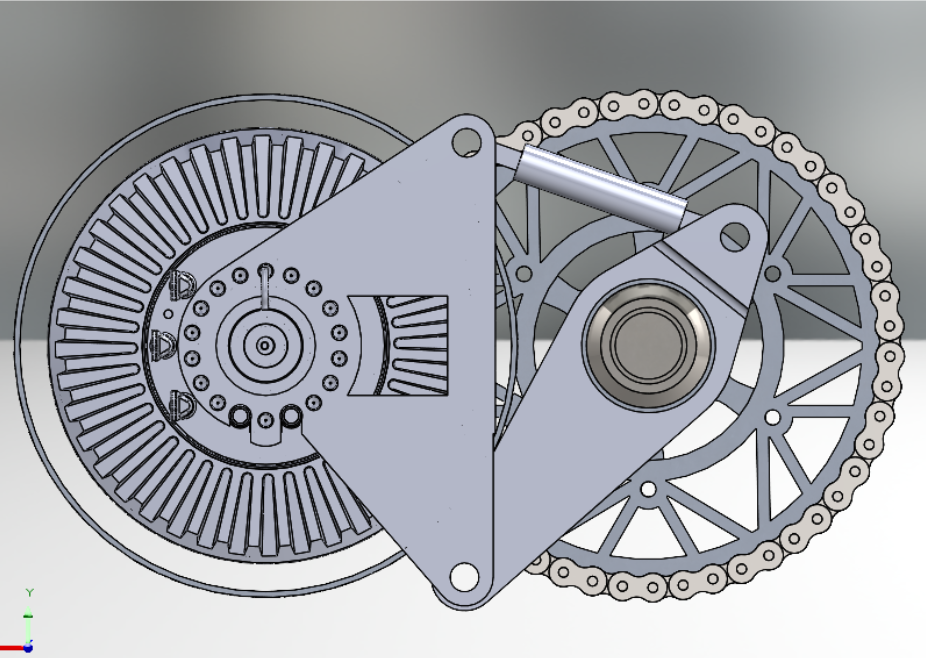

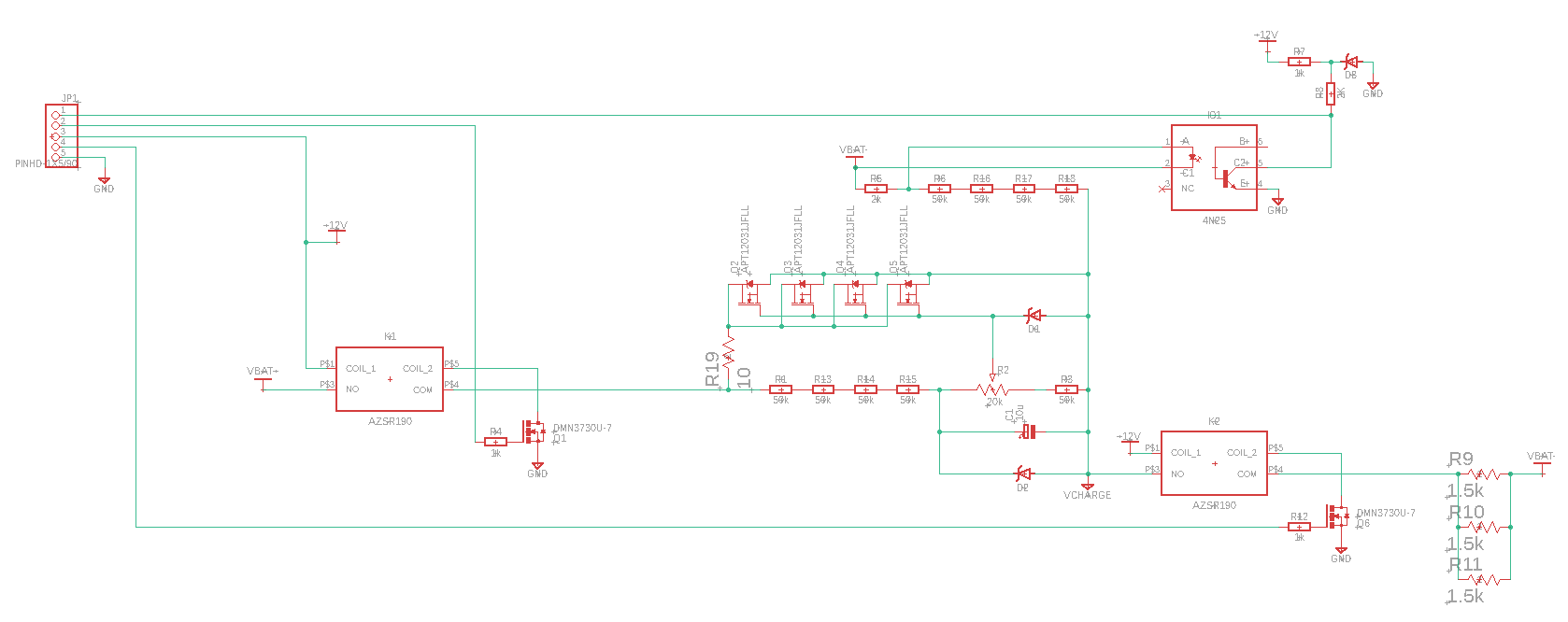

Powertrain Design Methodology Focuses, in order: Accumulator Electrical Specifications Key Rule Requirements Design Decisions Accumulator Electrical Design Battery Segment Requirements Key Rule Requirements Design Decisions CAD Manufacturing Wire Bond Specifications Fusing Specifications Requirements Validation Short circuit current of 2800A = (538V / (128series * 15mOhms) Accumulator Container Requirements Key Rule Requirements Design Decisions Accumulator Container…

-

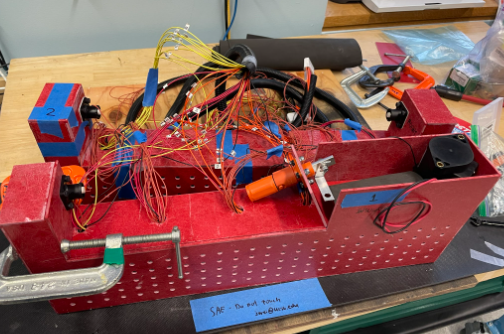

FSAE GR23 Battery Segment Design & Manufacturing SOP

Jason

Introduction This SOP provides a guide to safely manufacture and assemble battery segments of the GR23 electrical vehicle Overview Safety Considerations Battery Segment Design 26s5p li-ion cells per segment comprised of Enepaq 1x5p Sony VTC6 modules Necessary Materials, Tools, and Equipment Machining of Insulation Panels 2. Set up vacuum attachment and wear masks to minimize…

-

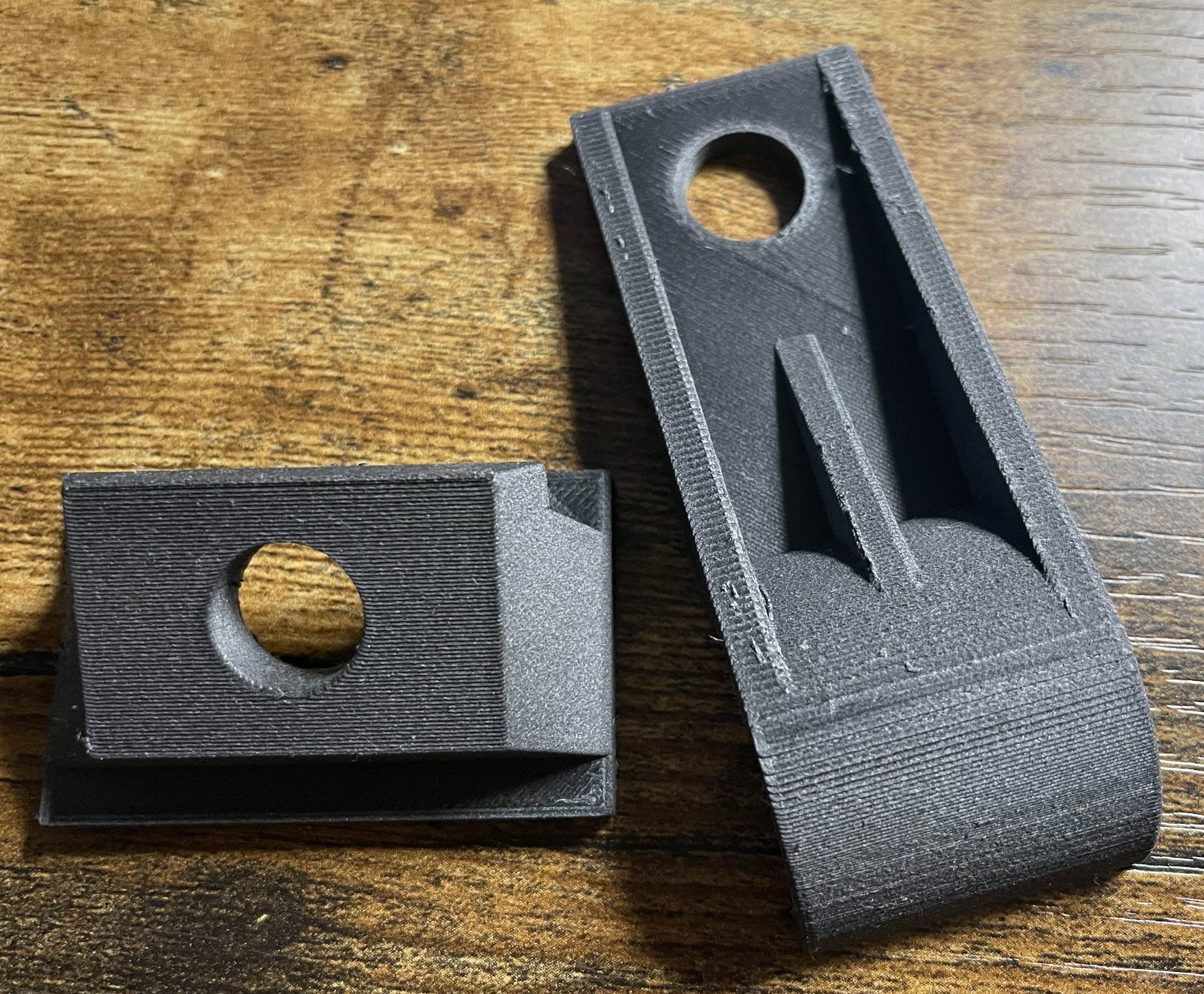

FSAE Accumulator Mounting

Jason

Introduction The accumulator container (a sheet metal box) houses the batteries, battery management system, and safety circuitry. Purpose The accumulator container has to be mounted to the chassis of the vehicle securely and rigidly while remaining removable. FSAE rules requires each of our mounts to be able to withstand 8000N of force in the forward…

Jason's portfolio

Creativity is all about connecting dots.